Porridge: from production to plate

On a recent visit to Zambia and Malawi, our Interim Executive Director, Marie Doyle, was taken on the journey of porridge. Here, she tells us what she learned.

There’s a lot more to porridge than I could ever have known!

‘Porridge’ is the school meal we serve to children in Malawi, Zambia and Zimbabwe. Made from a vitamin-enriched corn soya blend, known as CSB, this nutritious meal feeds more than 1.5 million children every school day, helping them to learn and grow.

I recently visited our school feeding programme in Zambia and Malawi, where our wonderful staff teams took me on the journey of porridge, from production to plate, so I could see first-hand how our life-changing school meals are made.

Production

Wherever possible, we serve locally procured food in our school feeding programmes. This supports the local community and its farmers, as well as the wider economy.

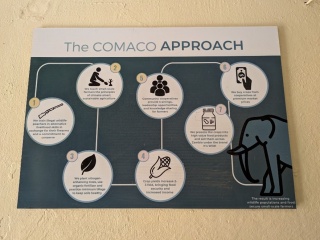

In Zambia, I visited COMACO (Community Markets for Conservation), a local supplier of CSB, and heard about how they support small-scale farmers to grow and sell their crops to be turned into porridge for Mary’s Meals.

COMACO sources all the raw materials to make CSB – except the vitamin blend that is added to fortify it – from local farmers. The company works with more than 350,000 small-scale farmers in Zambia’s Eastern Province. Each farmer produces only small yields of crops, they use this to feed their family, and then are able to sell any excess after that. This means thousands of geographically distant individuals producing very small amounts of food, which is a logistical challenge to harvest. COMACO gets around this by setting up cooperatives. These cooperatives support the farmers to improve their crop yields, through training and knowledge sharing on climate-smart, sustainable ways of farming. Half of all cooperative leadership positions are held by women.

Once the farmers in each cooperative have harvested their crops and kept what they need for their families, they take their excess maize and soya to local ‘bulking’ points where COMACO can collect the produce together in greater quantities. COMACO offers a promise to the farmers that they will always buy their produce at the going rate, so the farmers can be confident they will always have a market to sell to. This takes away the stress and burden of having to transport the small amount of produce they have left over to the market to try and find someone to sell it to.

Once collected, the crops are transported back to COMACO’s facilities where they are cleaned, graded and stored in bulk. Nothing goes to waste - any produce the company buys from the farmers that isn’t high enough quality for CSB is used to make other products, such as chicken feed.

What I loved learning about this part of the process is that many of the farmers’ own children eat Mary’s Meals. In a beautiful, circular journey, COMACO delivers the CSB back to the communities the crops came from, to be served in their schools.

Smith Kapaya, COMACO, Zambia

I spoke to Smith Kapaya from COMACO. He says: “COMACO is privileged to be one of the suppliers of CSB for Mary’s Meals. Once we receive orders for Mary’s Meals, we make the CSB and take it back into the communities – so the same small-scale farmers who are producing what COMACO is [using], their children are also benefiting through Mary’s Meals’ feeding programme. We value this market so much, because whatever proceeds we get through the sale of CSB for Mary’s Meals are also actually helping promote conservation in our rural communities.”

Processing

Next, I was taken on a tour of a COMACO factory in Zambia, where the CSB is manufactured. Just as the crops are sourced locally, the manufacturing process is carried out locally too, creating jobs in the area and further supporting the local communities. It was fascinating to see all the processes involved.

Manufacturing begins when Mary’s Meals places an order. The Mary’s Meals programme team carefully reviews the enrolment figures for each school to calculate the daily ration for each child. This is to calculate how much food the schools will need for a month and to make sure there is no wastage. Then the manufacturing process begins. First, the raw maize and soybeans are mixed in a machine. The mixture is then cooked at a high temperature. The hot mixture is then carried through a series of pipes into cooling bins, before being milled into a very fine powder, which is then mixed with sugar, vitamins and minerals to fortify the porridge. This mixture is the final CSB product, which is filled into 5kg and 20kg bags.

Each batch is tested before it leaves the premises to check the vitamin and mineral levels, as well as quantifying the fat, fibre, and protein content, and testing for toxins, fluoride and iron. Every batch is taste tested too. Quality control is strict – the manufacturers know exactly where the raw materials for each bag have come from, and they can trace every individual bag of CSB. The bags are stored for a maximum of a week before they are distributed to the schools.

Plate

The final stage of the porridge journey is getting it onto the plates – or rather, mugs – of the children who eat Mary’s Meals every school day. What really struck me about this part of the process is the precision involved.

Once the CSB is delivered to the schools, it is stored in a specially built storage room just off the kitchen in each school. The bags are always stacked in rounds of five so that, during the weekly stock takes, it’s easy to see how much is left. Stock is rotated in the school, and across the district, to make sure there is no wastage.

I visited several schools on my trip and was shown round the kitchens where the porridge is made by our wonderful Mary’s Meals volunteers. In Malawi, the volunteers arrive early each morning to make the porridge for the day. The porridge is cooked in large pots – each one holds 120 litres of porridge, which is enough to feed 298 children. To make the porridge, four buckets of cold water – 20 litres each – are poured into the pots. Then one 20kg bag of CSB is added, followed by another bucket of cold water. This exact process is very important – one of the volunteers told me it must be cold water to stop the mixture becoming lumpy! Once the mixture is all combined, it is stirred by hand then it is cooked over a fire for around 40 minutes. This seemed incredible compared with the couple of minutes it takes to cook my porridge at home in the microwave. There can be four or five pots cooking at a time – the kitchen gets incredibly hot! As the volunteers talked me through the cooking process, I could see how rigorous they were about following the protocol for making the porridge and making sure that everything is kept clean, and the cooking equipment is all well-maintained. They shared with me how grateful they were for the security offered to their children by the promise of Mary’s Meals, and I could see they took great pride in the vital part they play in the school feeding programme.

Once cooked, the porridge is transferred to smaller pots to be served just outside the kitchen. The children queue for their meal at ‘serving points’ which have been especially designed to ensure queuing is safe and orderly. This also helps to avoid spillages, which could lead to injuries from hot porridge – and wastage.

Finally, a daily log is taken of the number of children who have eaten. These logs, the porridge stocks, and the food preparation are checked in-person weekly by the Mary’s Meals school feeding officer assigned to the school. Everything is very carefully monitored to make sure the school feeding programme is running smoothly and efficiently.

A simple meal

We often say Mary’s Meals is a simple solution to hunger. A simple meal every school day that gives children energy to learn so that they can have a brighter future. What my porridge journey showed me was that what creates that simple meal in a mug is actually a very involved, but beautiful process – that doesn’t just feed hungry children, but supports their community and local economy too. Watching the joy on children’s faces as their brightly coloured mugs are filled with a nourishing meal and reflecting on what it took to get their porridge to them that day, I felt incredibly proud of our work.

Marie Doyle

Interim Executive Director, Mary’s Meals UK